The Advanced Gas-cooled Reactor Story

Advanced Gas-cooled Reactors (AGRs) hold a unique place in the history of nuclear power in the United Kingdom, marking the transition from Magnox reactors to a second generation of gas-cooled reactors with superior efficiency. Developed in the UK during the mid-late 20th century, these reactors were pivotal in continuing the contribution of nuclear power to the electricity grid in the UK: the UK once boasted 14 AGRs, providing a peak of approximately 16% of the UK energy demand in 2020.

Development of the Advanced Gas-cooled Reactor Design

The first AGR, the Windscale Advanced Gas-cooled Reactor (WAGR), was a small prototype – commissioned in 1963 at Sellafield, England. Not only was WAGR key to the development of the UK’s AGR fleet but it represents a global milestone – the first nuclear power reactor in the world to be fully decommissioned.

Evolving from the WAGR prototype, the UK fleet of Advanced Gas-cooled Reactors were developed as the successor to the Magnox generation of reactors, with changes to the fuel and design leading to superior efficiency.

Construction of the UK's Advanced Gas-cooled Reactor Fleet

The AGR programme commenced with huge ambition – construction off five twin reactor stations by three different design and build consortia: starting with Dungeness B, ordered in 1965 but not commissioned until 1983 due to problems with build complexity and strained labour relations at the time. Starting a year later, Hinkley Point B and Hunterston B, proved to be of a superior design and were in fact constructed and commissioned sooner than Dungeness B. The third design, at Heysham 1 and Hartlepool, sought to reduce cost and footprint – at the expense of more challenging construction. Learning from experience, the final two AGRs, at Heysham 2 and Torness, returned to an upgraded version of the Hinkley / Hunterston design.

Operational History

Between 1965 and 1988, the UK built 14 advanced gas-cooled reactors, two at each of seven sites.

Now, in the UK, the reactors that once made up the AGR fleet are coming to the end of their operation, with Dungeness B, Hunterston B and Hinkley Point B all having ceased generation. The remaining reactors are currently planned to close by the year 2030, though this is subject to review – depending upon inspections of their graphite cores.

Advantages and Challenges of an Advanced Gas-cooled Reactor

The changes to fuel were facilitated by the UK discovering how to enrich uranium efficiently; therefore, the advanced gas-cooled reactor was designed to use enriched uranium oxide fuel, as is also used in PWRs. Compared to PWRs, AGRs have a greater thermal efficiency of 41 % (compared with 34 %).

AGRs lack thermal feedback, a form of passive safety present in PWRs where an increase in coolant water temperature decreases the criticality of the reactor – failing to safe. However, AGRs have a much larger reactor pressure vessel and thus a lower power density. Despite the absence of thermal feedback, upon a criticality failure it takes several days before the reactor will heat beyond cooling capability.

Legacy and Decommissioning

Whilst some of the UK’s advanced gas-cooled reactor fleet are still generating power, decommissioning is the next stage of the nuclear life cycle and is imminent for these reactors. This is due to AGRs being life-limited by cracking of graphite within their cores.

How does an Advanced Gas-cooled Reactor work?

Advanced gas-cooled reactors are a type of gas-cooled, graphite-moderated nuclear reactor that uses uranium oxide as fuel, enriched to 2.5-3.5% uranium-235.

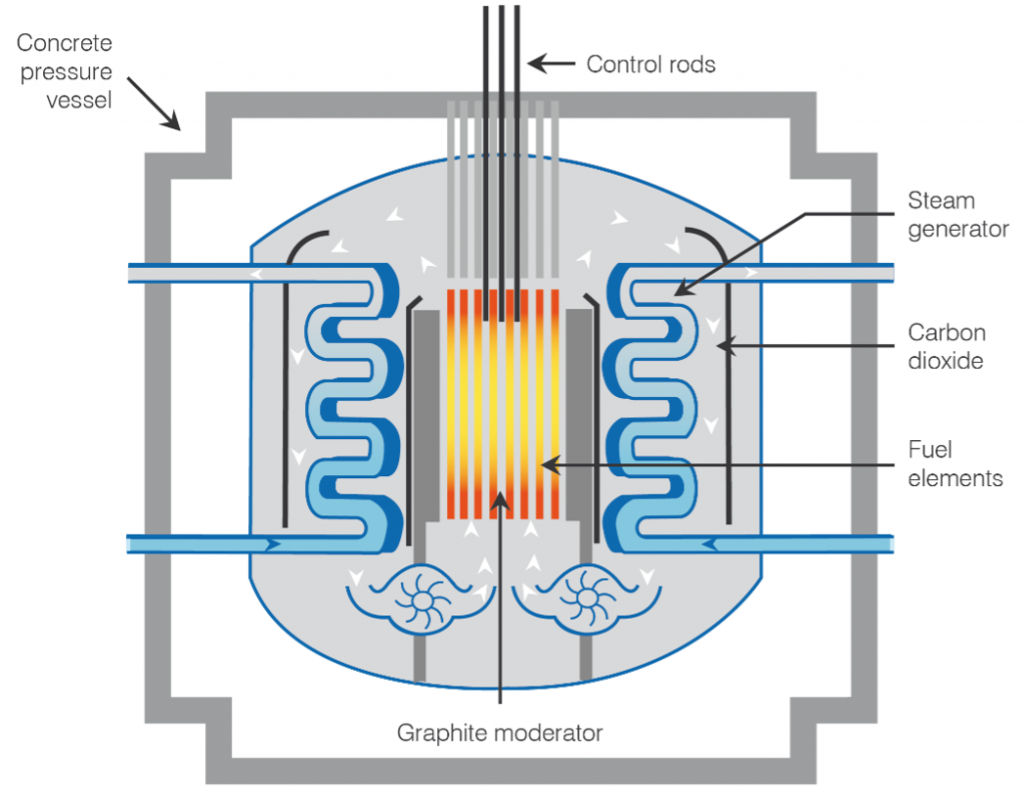

In an AGR, carbon dioxide gas is circulated through the reactor core to transfer heat from the fuel rods to a boiler (steam generator), where water is converted to steam to drive turbines and generate electricity. The graphite moderator slows down neutrons to sustain the nuclear chain reaction.

How does an Advanced Gas-cooled Reactor compare?

AGRs lack thermal feedback, a form of passive safety present in PWRs where an increase in coolant water temperature decreases the criticality of the reactor – failing to safe. However, AGRs have a much larger reactor pressure vessel and thus a lower power density. Despite the absence of thermal feedback, upon a criticality failure it takes several days before the reactor will heat beyond cooling capability.

Uranium Dioxide Fuel

The fuel rods used in advanced gas-cooled reactors contain uranium dioxide powder, enriched to 2.5-3.5% uranium-235 and pressed into pellets. An AGR fuel assembly contains 36 fuel rods, each comprising 64 uranium dioxide pellets and clad in stainless steel..

This differs from first generation Magnox reactors, which used natural uranium fuel. This change was facilitated by the UK discovering how to enrich uranium efficiently and necessitated by the use of stainless steel cladding on AGR fuel rods (required to withstand corrosion at the higher operating temperatures).

Stainless Steel Cladding

The cladding on advanced gas-cooled reactor fuel rods must be able to withstand high temperatures of up to 640oC, without brittle fracture or corrosion. Therefore, stainless steel was chosen as the cladding material for use on AGR fuel rods. Stainless steel has a higher neutron capture cross-section than the Magnesium-Aluminum Non-OXidising alloy cladding used on the fuel rods of Magnox reactors, hence the need for the uranium dioxide fuel to be enriched.

Graphite Moderator

Advanced gas-cooled reactors use graphite as a neutron moderator. The graphite slows down the fast neutrons produced during fission to thermal energies, which are more effective at sustaining the chain reaction.

The use of graphite allowed the reactors to maintain a stable and controlled fission process, contributing to their reliability and safety. However, the graphite core can be a life-limiting factor for these reactors. This is because, over time, the graphite ages by an interaction with radiation in the reactor core and the coolant gas.

Carbon Dioxide Coolant

Another relatively unique feature of advanced gas-cooled reactors is their use of carbon dioxide (CO2) gas as a coolant. This coolant gas circulates around the reactor core and primary circuit at pressures up to 40 bar and at temperatures up to 640 °C, due to absorbing the heat generated by nuclear fission.

Hot coolant gas is then used to produce steam in the secondary circuit’s boiler, exchanging heat with cold water. Simultaneously, as it transfers heat, the gas cools back down so it can recirculate and remove more heat from the nuclear reactor core. As well as this, the water fed to the steam generator is heated up sufficiently high that it evaporates and forms high energy steam. It is this steam that uses its kinetic energy to drive turbines that generate electricity. The steam then enters the condenser, condensing back to liquid water.

The choice of carbon dioxide as a coolant provides several advantages, including chemical inertness and low neutron absorption.

Where are the Advanced Gas-cooled Reactor Sites?

Dungeness B

Dungeness B, located on the Dungeness headland in Kent, England, was the UK’s first AGR to start construction. Commissioned in 1983, it featured two reactors with a combined capacity of 1120 MWe.

After ceasing generation in 2018, Dungeness B moved into the defueling phase of its life cycle on 7 June 2021.

Hinkley Point B

Hinkley Point B, located on the Bristol Channel coast in Somerset, England, was the first AGR to generate electricity for the UK’s national grid. Commissioned in 1976, it featured two reactors with a combined capacity of 965 MWe.

The station operated until August 2022, generating over 311 TWh of electricity during its lifetime. At the time of entering defueling, prior to decommissioning, Hinkley Point B was the most productive nuclear power station in the history of the UK. There are now plans for a third station at the site, a PWR known as Hinkley Point C.

Hunterston B

Hunterston B, located in Ayrshire on the west coast of Scotland, was one of the UK’s early AGR nuclear power stations. Commissioned in 1964, it featured two reactors, with a combined capacity of 965 MWe.

The station operated until 2022, producing 297.4 TWh of electricity. In 2022, Hunterson B entered the decommissioning phase, starting with defueling. Hunterston B’s Reactor 3 the first advanced gas-cooled reactor to be completely defueled.

Hartlepool

Hartlepool nuclear power station is located on the northern bank of the River Tees, in northeast England.

Sharing a design with Heysham 1, Hartlepool was commissioned in 1983. With a combined capacity of 1185 MWe, the station’s two reactors are capable of supplying electricity to 2 million homes. Hartlepool is currently expected to operated until 2027.

Heysham 1

Heysham, near Lancaster on England’s northwest coast, is the only site home to two AGRs, with a combined four reactors.

Sharing a design with Hartlepool, Heysham 1 was commissioned in 1983. The station’s two reactors boast a combined capacity of 1155 MWe, and are currently expected to operate until 2027.

Heysham 2

Heysham, near Lancaster on England’s northwest coast, is the only site home to two AGRs, with a combined four reactors. Heysham 2 was commissioned in 1988 and the station’s two reactors boast a combined capacity of 1230 MWe; they are currently expected to operate until 2030.

On 1 August 2016, Heysham 2’s Reactor 8 broke the world record for the longest continuous generation by a single nuclear power plant – 940 days. This was made possible because AGRs are capable of on-load refuelling. As BWRs and PWRs cannot be refuelled whilst generating, this record is unlikely to ever be broken.

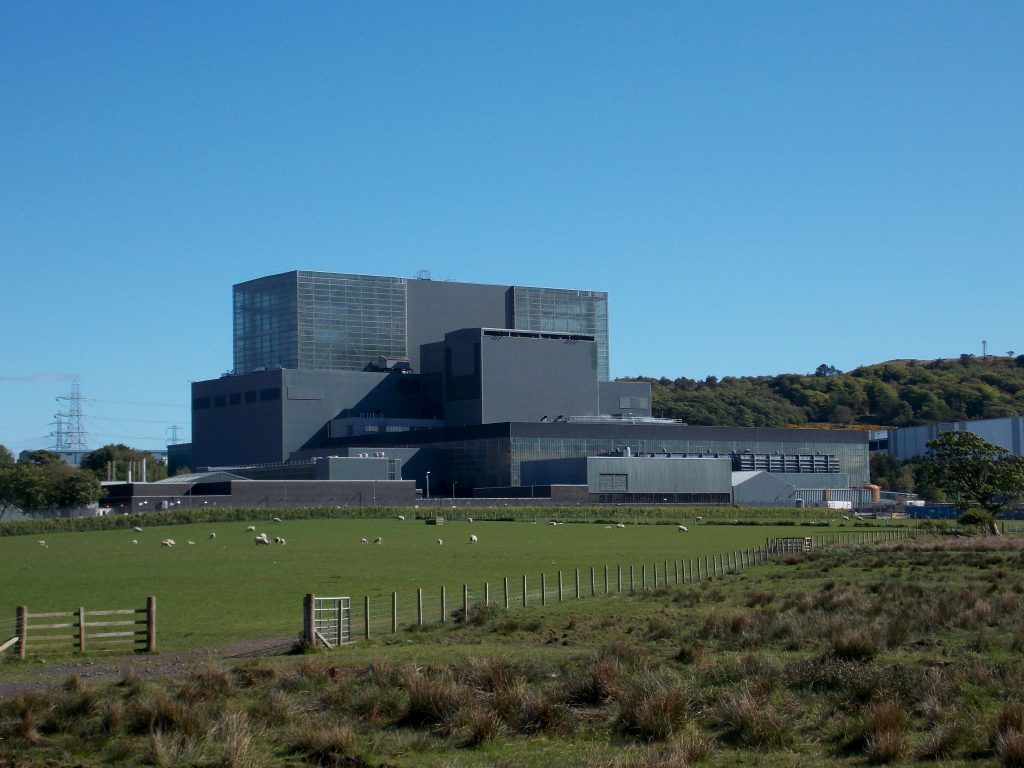

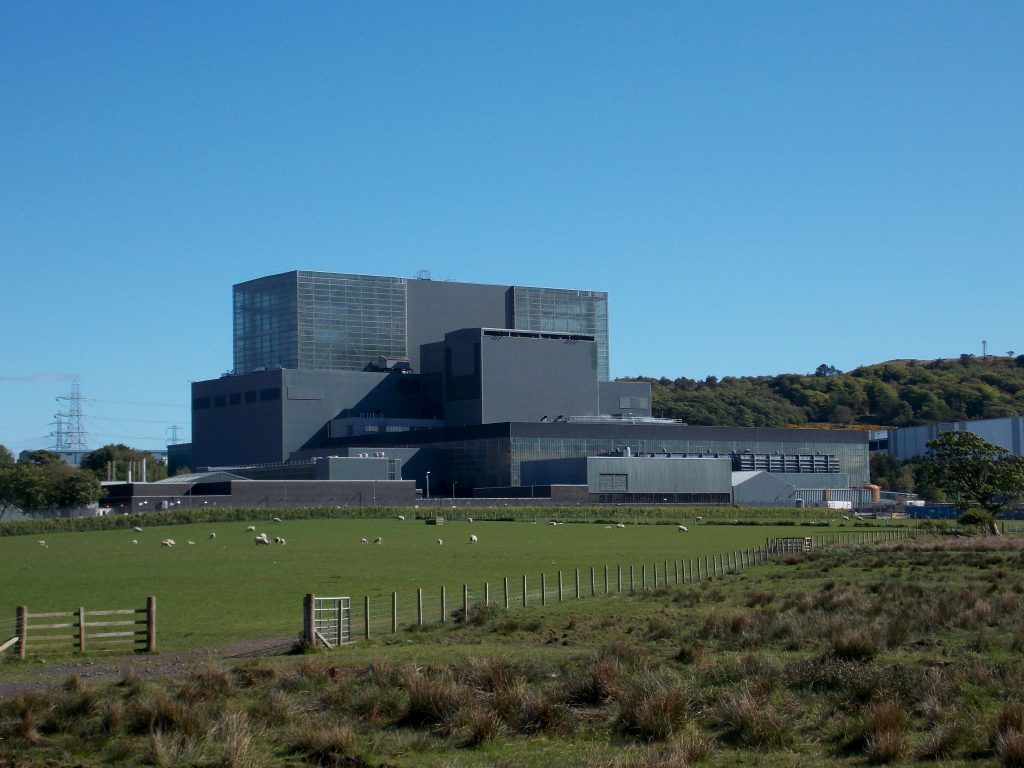

Torness

Torness nuclear power station, located 33 miles east of Edinburgh, in Scotland, is home to two reactors with a combined capacity of 1190 MWe.

The power station was commissioned in 1988, sharing a design with Heysham 2, and is expected to generate electricity until 2030.

Decommissioning the Advanced Gas-cooled Reactors

The Decommissioning Process

Whilst Hartlepool, Heysham 1, Heysham 2 and Torness are still generating power, decommissioning is the next stage of the nuclear life cycle and is imminent for these reactors. This is due to advanced gas-cooled reactors being life-limited by cracking of graphite within their cores. Dungeness B, Hinkley Point B and Hunterston B have already ceased generation and entered decommissioning.

The decommissioning strategy of the UK AGR fleet will follows the following structure:

- Defueling: This process is expected to take 3-10 years, whilst the spent fuel from the reactor is removed and stored in cooling ponds. This stage handles 99% of the radioactivity on the entire site.

- Deconstruction of the Site: This process will take 10-15 years where all non-essential buildings (excluding the reactor) and structures are decontaminated and deconstructed.

- Safe Store Period: The remains of the site such as the reactor will be left covered for 70-85 years while the activity level naturally drops to much safer levels.

- Final Destruction: This process will take roughly 10-15 years were all remaining equipment, such as the reactor, is dismantled and processed.

- Final Remediation: After all equipment and building have been deconstructed and disposed, final clean up takes place restoring the site back to the green field it once was.

Challenges

Safety: Ensuring the safety of workers and the public is paramount. Strict safety protocols and continuous monitoring are essential to prevent radiation exposure and accidents.

Technical Complexity: The decommissioning process involves intricate engineering challenges, particularly in dismantling radioactive components and managing waste.

Cost: Decommissioning is a costly endeavour and a ring-fenced budget for decommissioning the AGRs allocated to the Nuclear Decommissioning Authority (NDA).

Time: The entire decommissioning process can take several decades.

Case Study: Hunterston B

Hunterston B was the first of the UK’s full-scale advanced gas-cooled reactor stations to enter the defueling phase.

Reactor 3, named to avoid confusion with Reactors 1 and 2 at Hunterston A, was completely defueled within 16 months; this allowed defueling of Reactor 4 to commence to take place between September 2023 and December 2024.

Spent fuel is transferred to the Sellafield site in Cumbria, for long-term storage, prior to final disposal in a Geological Disposal Facility.

Explore Further

Choose from the articles below to continue learning about nuclear.

Magnox Reactors – At the Forefront of a New Age

Gas-Cooled Fast Reactor (GFR) – High-Efficiency, Next-Gen Nuclear Power

Advanced Modular Reactor (AMR) – The Future of Nuclear Energy Explained

Boiling Water Reactor (BWR) – an introduction to this type of nuclear power plant

Did you know? Explore Nuclear also offers great careers information and learning resources.

Below you can find references to the information and images used on this page.

Content References

- EDF Energy – Defueling success as first reactor fuel free at Hunterston B in Scotland

- EDF Energy – UK nuclear power stations

- Energy Encyclopedia – Gas Cooled Reactors

- Frazer-Nash Consultancy – Graphite modelling of ageing nuclear power generation assets

- IAEA -General Design and Principles of the Advanced Gas-Cooled Reactor (AGR)

- NAO – Decommissioning of the AGR Nuclear Power Stations

- ONR – Graphite Core Ageing

- ONR – Operational Reactors

- UK Government – Nuclear Electricity in the UK/

- Westinghouse – Advanced Gas-cooled Reactors

- WNA – Nuclear Power in the UK

- WNN – Podcast: What next for UK’s record-setting Heysham 2 nuclear power plant?

Image References

- AGR fuel pin, about 1958-1982 – Science Museum Group – CC BY-NC-SA 4.0, © The Board of Trustees of the Science Museum

- AGR Schematic – World Nuclear Association (courtesy of)

- Dungeness B Nuclear Power Station – Sandpiper – Public Domain

- Hartlepool Nuclear Power Station – Geni – CC BY-SA 4.0

- Hartlepool Nuclear Power Station – D Wells – CC BY-SA 4.0

- Heysham Nuclear Power Stations – David Merrett – CC BY 2.0

- Heysham Nuclear Power Stations – Carroll Pierce – CC BY-SA 2.0

- Heysham 2 Nuclear Power Station – Karl and Ali – CC BY-SA 2.0

- Hinkley Point B Nuclear Power Station – Robin Somes – CC BY-SA 2.0

- Hunterston B Nuclear Power Station – Jonathonchampton – CC BY-SA 3.0

- Hunterston B Nuclear Power Station – Linear-Vertex – CC BY-SA 4.0

- Reactor Graphite – Science Museum Group – CC BY-NC-SA 4.0, © The Board of Trustees of the Science Museum

- Torness Nuclear Power Station – Alessandro Ambrosetti – CC BY-SA 4.0

- Torness Nuclear Power Station – Pixabay (courtesy of)

- Windscale Advanced Gas-cooled Reactor Decommissioning – IAEA – CC BY 2.0