How does a Boiling Water Reactor work?

As the name suggests, a Boiling Water Reactor (BWR) uses water as a coolant and as a moderator.

Extremely pure (demineralised) water flows around the primary circuit and through the core, where nuclear fission generates heat. Water in the primary circuit is hot, heated to around 285°C and is permitted to boil – only reaching pressures up to 7.5 MPa, 75 times greater than atmospheric pressure.

The steam generated occupies about 12-15% of the volume of the reactor pressure vessel. After being dried by steam separators, the steam flows directly to turbines within the primary circuit. As the turbines spin, electricity is generated.

Fuel. Moderator. Coolant.

Fuel

Fuel

Fun fact: BWRs can last up to 2 years without being refuelled!

Moderator

Moderator

Coolant

Coolant

BWR Safety Systems

A key safety feature of a Boiling Water Reactor (BWR) is the containment shielding that surrounds the reactor pressure vessel. This stops any radiation getting to the outside environment, and also is reinforced to stop things getting in. This includes extreme weather events like hurricanes, missiles and even stops planes from crashing through it!

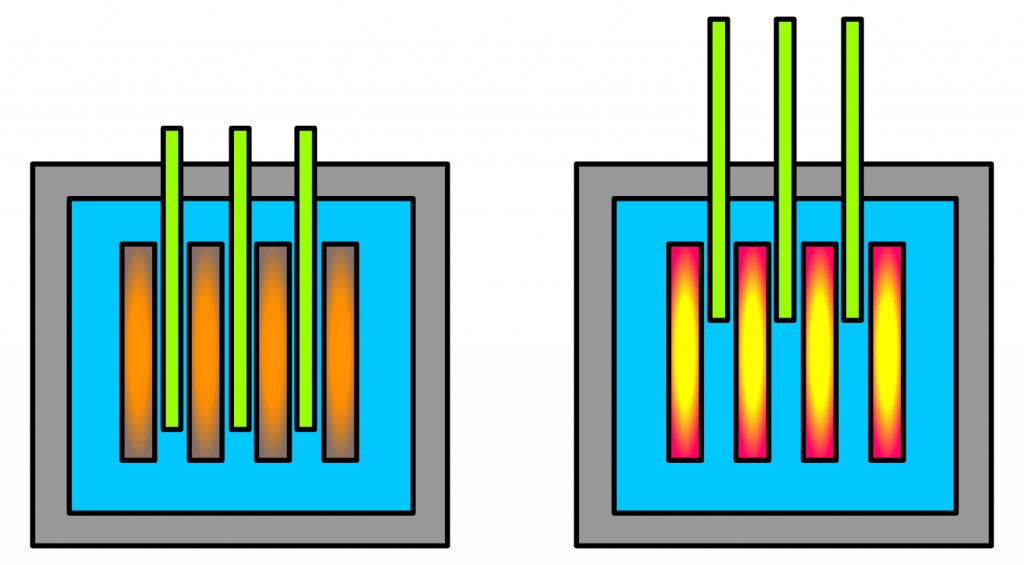

In a BWR, the rate of fission can be readily controlled by changing the position of the control rods within the core.

Control Rods typically contain boron, with a high neutron absorption cross-section. Therefore, if the control rods are inserted further into the core, more neutrons are absorbed and the rate of fission decreases.

This complements other methods, such as introducing gadolinia into the coolant water (a “poison” that also absorbs neutrons).

Water is a good moderator because it is passively safe due to what’s called ‘Thermal Feedback‘.

This is a key reason why BWRs are so safe and widely used.

‘Thermal Feedback’ means that as the water gets hotter the power output goes down, or vice versa, because:

- As water heats up, its molecules become less dense; so,

- Each neutron is moderated by fewer water molecules; so,

- Moderation decreases overall; so,

- There are fewer thermal neutrons; and,

- The rate of fission decreases.

A scram is a sudden reactor shutdown that can be undertaken in an emergency scenario.

The control rods are dropped rapidly into the reactor core to stop the fission reaction occurring. This is a scram.

After a scram, fuel will still give off decay heat and must continue to be cooled.

If the reactor loses coolant due to an accident, the water must be replaced so that the reactor does not over heat.

This involves a variety of systems, which vary by design, but may include a high pressure coolant injection system, containment cooling system and a gravity-driven core cooling system that takes advantage of natural convection.

Collectively, these are known as the Emergency Core Cooling System, or ECCS.

Look Inside a Boiling Water Reactor

Explore Further

Choose from the articles below to continue learning about nuclear.

Fission – How splitting an atom creates energy

Supercritical Water Reactor (SCWR) – Steam, Speed and Sustainability

Magnox Reactors – At the Forefront of a New Age

Decommissioning – What goes up, must come down

This page is part of one of our ‘Journeys through Nuclear‘. Continue your journey using the selection below.

Boiling Water Reactor

The second most common reactor type boils its coolant directly, turning it into steam.

Magnox Reactor

Gas-cooled Magnox reactors were the UK’s first generation reactor fleet.

Coming Soon →

Advanced Gas-Cooled Reactor

Advanced Gas-Cooled Reactors, or AGRs, are the UK’s second generation reactor fleet.

Advanced Modular Reactor

Advanced Modular Reactors, or AMRs, are Generation IV reactors – the future of nuclear.

Did you know? Explore Nuclear also offers great careers information and learning resources.

Below you can find references to the information and images used on this page.